Welcome to visit our website of Charming Chemical Equipment Co.,Ltd.

It’s safe to assume that our readers have a diverse level of knowledge when it comes to glass lined steel. Maybe you’re an experienced customer with glass lined reactors currently operating in your facility. Or perhaps you’ve heard about glass lined steel but don’t have a solid understanding of how this unique material of construction can benefit your process. Some of you maybe have even stumbled upon this blog post having zero familiarity on the subject but are interested in learning about its basic properties and what makes glass lined equipment so great compared to standard stainless steel and alloy vessels?

To gain a full appreciation for glass lining and its versatility, you don’t need to be an expert, but it is helpful to better understand the fundamentals by knowing the steps involved in making a vessel. The manufacture of glass lined steel equipment is a combination of three processes: production of the glass, steel fabrication, and combining the glass and steel. Here’s a comprehensive look at these processes and exactly what happens at each phase of fabrication.

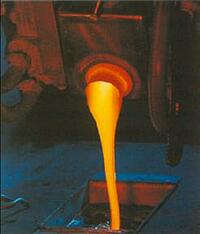

The primary step in this sequence of events is to create the enamel that is used to construct the glass lining. Each batch of enamel is comprised of carefully selected and rigidly controlled raw materials, which are melted in a rotary furnace at about 2,500°F (1,400°C). The melted glass in then poured into water. This sudden tempering breaks the enamel into particles called “frit”. The frit is then dried, milled, and screened into a powder. The enamel is available in two colors (blue and white), each having exactly the same chemical and mechanical properties. The preference for one color versus the other is typically determined by which enables better visibility for cleaning purposes based on the chemicals involved in the end user’s application.

glass lined vessels are constructed to have a very unique geometry, so the steel fabrication is an equally important part of the manufacturing. Once the heads are received, the first step is to punch pilot holes locating the nozzles. The nozzle area is heated until the steel becomes ductile and a die can be hydraulically forced through the pilot hole. This action is called “swaging”.

It is important to note here that nothing can be welded to the outside of the finished vessel. Therefore, provisions for attaching the jacket, drive mountings, and other exterior accessories must be made before the vessel is glassed. The following welds are conducted to fuse the parts of the vessel body together and prepare the vessel for jacket installation:

The inner shell to the head (in the case of close-welded reactors)

The bottom head to the inner shell

The jacket closure ring to the vessel bottom head around the outlet nozzle(s)

The jacket closure ring to the vessel top head around the knuckle radius

Finally, the entire interior and exterior is steel grit blasted and prepped for glassing.

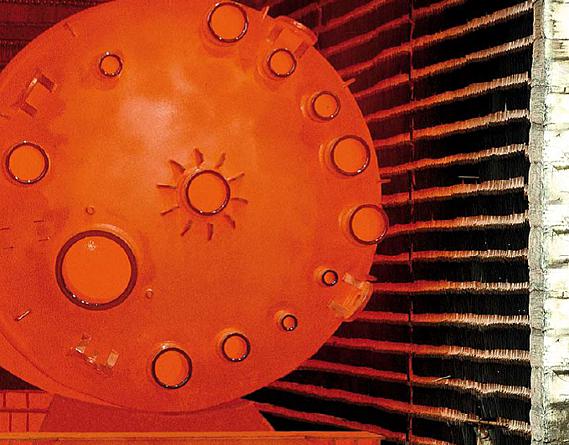

Once the steel is made suitable for glassing, the final procedure of combining the glass and steel can take place. The first coat of glass is called the ground coat, also known as “slip”. The ground coat is specially formulated with emulsifying agents to promote adherence to the steel and does not have any corrosion resistance. After the glass suspension is sprayed onto the prepared steel tank it is allowed time to dry. The vessel is then transported to an electric furnace via a rail cart where it is fired at a specific temperature for a standard length of time to “fuse” the glass to the steel. The item is then transferred to a controlled cooling booth that helps to reduce built-in stress in the glass.

Watch the video of a vessel being extracted, red hot, from the electric furnace and getting transferred to a cooling booth (you might want to turn the volume down a notch on your PC when you watch this):

Subsequent coatings called cover coats are applied in the same respect (spray, dry, heat, cool), with the one significant difference being the lower temperature at which the cover coats are fired at to prevent the ground coat from bleeding through. Quality control spark and thickness tests between coats are performed to ensure the highest quality of the finished lining. The procedure is repeated until the desired glass thickness is attained. The standard thickness of a completed vessel is between 40 and 90 mils (1-2mm). The result is an impermeable, smooth coating of glass that is ideal for pharmaceutical and chemical applications. The glass to steel bond is very strong, with strength of approximately 16,000 psi (similar to that of pre-stressed concrete!).

When the glassing process is finished the vessel then enters the welding area to have the jacket installed. The jacket shell and jacket head have already been welded together and are now ready to be welded onto the closure rings that are on the vessel. A diaphragm is welded to the closure ring to compensate for expansion and contraction of the jacket. A hydro test, in which the vessel is filled with water, is performed for quality assurance. Following completion, the vessel is blasted and prepped for painting and then moved to the paint booth. Based on the specifications of the order, nozzles will be supplied with the appropriate ANSI Class split loose flange (these flanges are preferred over one-piece flanges for glass lined vessels because they eliminate heavier nozzle forgings that could cause glassing problems.) Finally, an additional quality control check and spark test are conducted and the vessel is ready to ship.